combo vending machine manufacturer

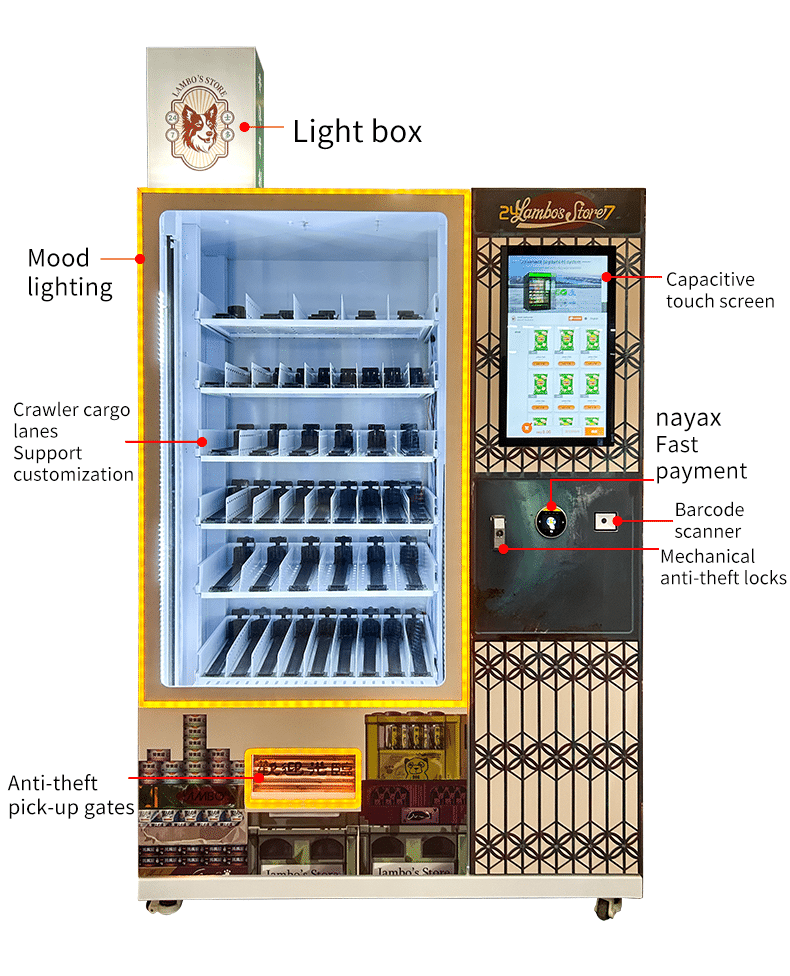

A combo vending machine manufacturer specializes in designing and producing versatile automated retail solutions that combine multiple product categories in a single unit. These sophisticated machines integrate advanced technologies, including touchscreen interfaces, cashless payment systems, and remote monitoring capabilities. The manufacturing process encompasses precision engineering, incorporating temperature control systems that maintain different zones for various product types, from beverages and snacks to fresh food items. These manufacturers employ state of the art production facilities equipped with quality control measures to ensure each machine meets strict reliability and durability standards. The machines feature modular designs that allow for customization based on specific client needs, with options for various product capacities and dispensing mechanisms. Advanced inventory management systems are built in, enabling real time stock monitoring and automated reordering processes. The manufacturers also implement IoT connectivity features, allowing operators to access sales data, maintenance alerts, and performance metrics remotely. Environmental considerations are integrated into the design process, with energy efficient components and eco friendly refrigeration systems. These manufacturers often provide comprehensive after sales support, including maintenance services, software updates, and technical assistance to ensure optimal machine performance throughout its lifecycle.