quality helmet cleaning machine

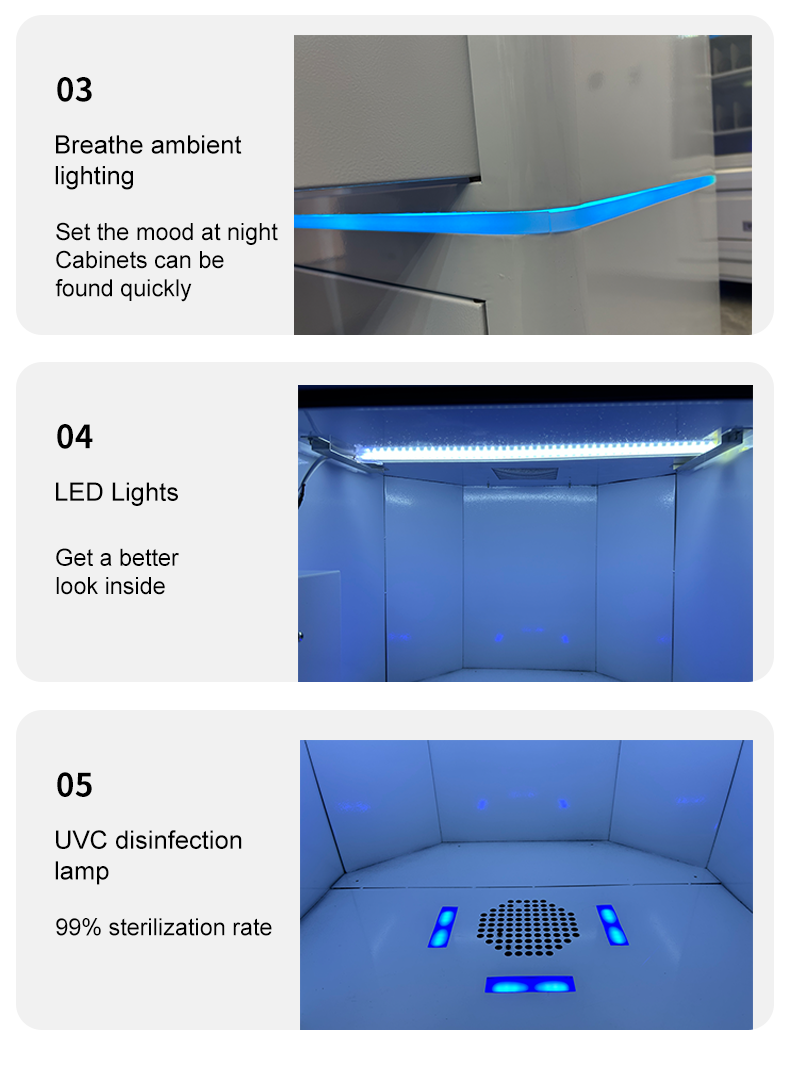

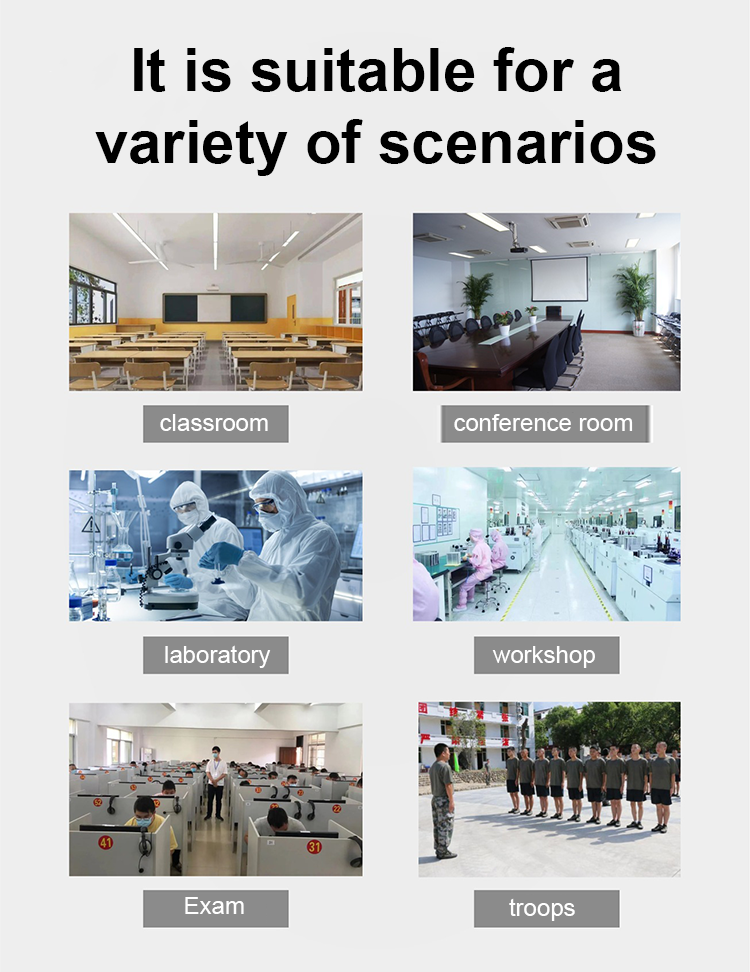

The quality helmet cleaning machine represents a groundbreaking solution in protective equipment maintenance, offering comprehensive sanitization and care for various types of helmets. This advanced system employs a combination of UV-C light technology, ultrasonic cleaning mechanisms, and precision-controlled drying processes to ensure thorough cleanliness and hygiene. The machine features a spacious cleaning chamber that accommodates multiple helmets simultaneously, making it ideal for commercial facilities, sports centers, and professional equipment maintenance services. Its automated operation system includes pre-programmed cleaning cycles that optimize the cleaning process based on helmet type and material composition. The machine's innovative design incorporates specialized nozzles that deliver cleaning solution to every surface, including hard-to-reach areas, while its integrated filtration system removes dirt, sweat, and bacterial residue effectively. Advanced sensors monitor temperature and humidity levels throughout the cleaning cycle, ensuring optimal conditions for both cleaning efficacy and material preservation. This technology makes it particularly valuable for organizations managing large volumes of protective equipment, such as rental facilities, emergency services departments, and professional sports teams.