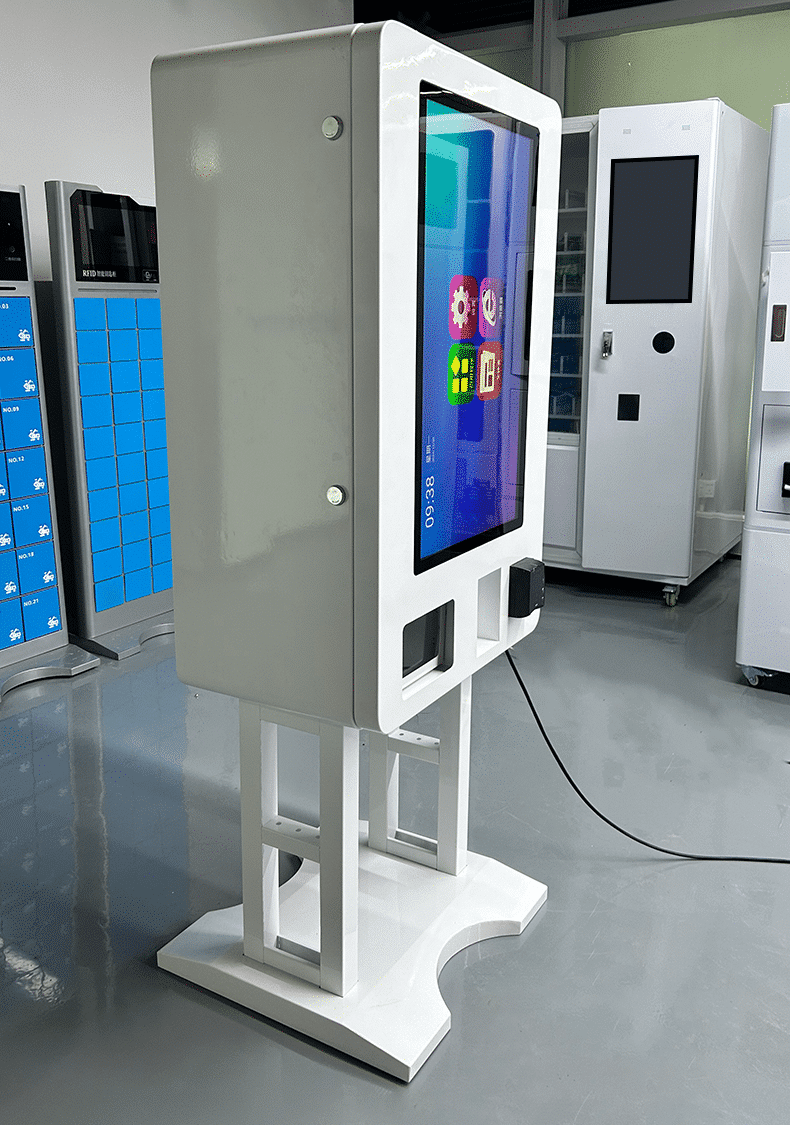

pensteril topi keledar

Pensteril topi keledar mewakili penyelesaian termaju dalam penyelenggaraan peralatan perlindungan peribadi, menggabungkan teknologi UV-C termaju dengan proses sanitasi pintar. Peranti inovatif ini dengan cekap menghapuskan sehingga 99.9% bakteria, virus dan mikroorganisma berbahaya lain yang biasanya terkumpul pada permukaan topi keledar melalui penggunaan biasa. Sistem ini mempunyai ruang pensterilan yang luas yang direka untuk menampung pelbagai saiz dan gaya topi keledar, daripada topi keledar motosikal dan sukan kepada peralatan keselamatan industri. Beroperasi pada prinsip sanitasi 360 darjah yang canggih, unit ini menggunakan berbilang lampu UV-C yang diposisikan secara strategik untuk memastikan liputan lengkap kedua-dua permukaan luaran dan dalaman. Kitaran pensterilan biasanya selesai dalam masa 8-10 minit, menjadikannya cekap masa dan praktikal untuk kegunaan harian. Ciri keselamatan lanjutan termasuk mekanisme tutup automatik dan penderia pintu untuk mengelakkan pendedahan UV. Panel kawalan digital menawarkan operasi mesra pengguna dengan program pratetap untuk jenis topi keledar yang berbeza dan tahap pencemaran. Ciri tambahan termasuk sistem operasi bebas ozon, menjadikannya mementingkan alam sekitar dan selamat untuk kegunaan dalaman. Reka bentuk padat unit membolehkan penempatan yang mudah dalam pelbagai tetapan, daripada kemudahan sukan profesional kepada garaj peribadi, manakala pembinaannya yang tahan lama memastikan kebolehpercayaan jangka panjang dan prestasi yang konsisten.