tagagawa ng elevator vending machine

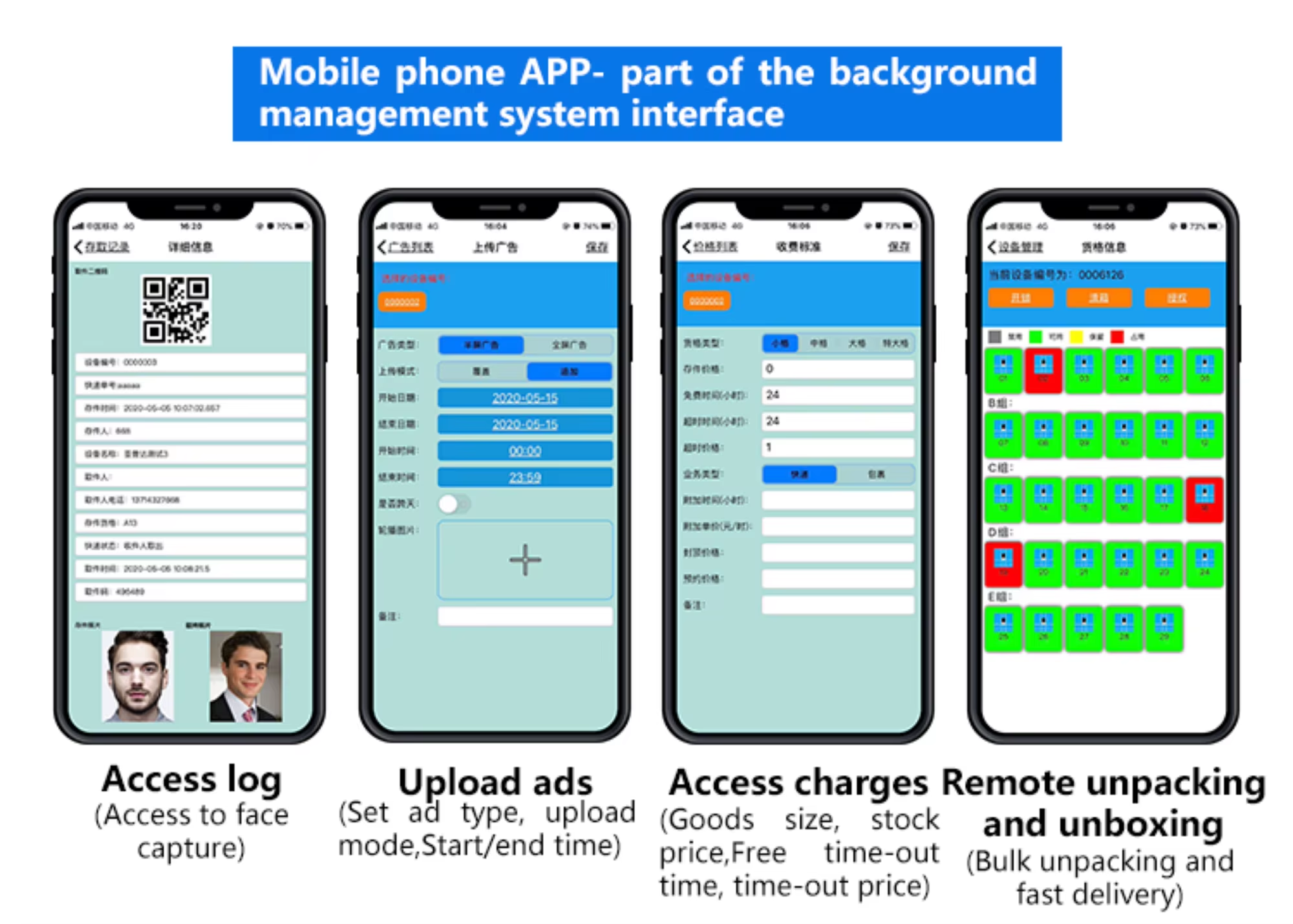

Ang isang tagagawa ng elevator vending machine ay nag-specialize sa pagdisenyo at produksyon ng mga inobatibong automated retail solusyon na pinagsasama ang kaginhawahan ng tradisyunal na vending machine kasama ang space-saving na benepisyo ng mga vertical transportation system. Ang mga sopistikadong makina ay gumagamit ng advanced robotics at smart delivery mechanism para mailabas ang produkto sa maramihang antas, pinapakain ang retail space efficiency sa mataong lokasyon. Kasama sa mga sistema ang cutting-edge touchscreen interface, mobile payment integration, at real-time inventory management capability. Ang mga makina ay may temperature control units upang mapanatili ang sariwa at kalidad ng produkto, na angkop para sa iba't ibang item tulad ng inumin, meryenda, electronics, at personal care products. Ang tagagawa ay gumagamit ng precision engineering upang masiguro ang maayos na paghahatid ng produkto habang binabawasan ang mekanikal na pagsusuot at pinapanatili ang operational reliability. Ang kanilang mga sistema ay may remote monitoring capabilities, na nagpapahintulot sa mga operator na subaybayan ang benta, pamahalaan ang imbentaryo, at agad na tugunan ang teknikal na problema. Ang mga makina ay idinisenyo gamit ang modular components para madaliang maintenance at upgrade, na nagsisiguro ng long-term value para sa mga operator. Ang mga solusyon ay partikular na mahalaga sa mga lokasyon tulad ng paliparan, ospital, gusaling opisina, at institusyong pang-edukasyon kung saan mahalaga ang space optimization at 24/7 produktong nakaka-access.