The logistics industry faces mounting pressure to reduce operational expenses while maintaining service quality and customer satisfaction. Traditional delivery methods often involve multiple delivery attempts, increased fuel consumption, and substantial labor costs that eat into profit margins. Courier companies are increasingly turning to innovative solutions to streamline their operations and smart parcel lockers represent a transformative approach to addressing these challenges. These automated delivery systems offer a comprehensive solution that fundamentally changes how packages are distributed in urban and suburban environments.

Understanding the Cost Structure of Traditional Parcel Delivery

Labor-Intensive Delivery Operations

Traditional parcel delivery systems rely heavily on human resources, creating significant operational overhead for courier companies. Delivery drivers must navigate complex routes, spend time locating recipients, and handle multiple delivery attempts when customers are unavailable. This labor-intensive approach results in substantial wage expenses, benefits costs, and training investments that directly impact the bottom line. The time spent on each delivery attempt often exceeds the actual transit time, creating inefficiencies that compound throughout the delivery network.

The challenge becomes more pronounced during peak seasons when courier companies must hire temporary staff to handle increased package volumes. These seasonal workers require training, equipment, and supervision, adding layers of complexity and cost to operations. Additionally, the physical demands of package delivery contribute to higher turnover rates, requiring continuous recruitment and training cycles that drain resources from core business activities.

Vehicle and Fuel Consumption Expenses

Fleet management represents another significant cost center for courier companies operating traditional delivery models. Delivery vehicles require substantial capital investments, regular maintenance, insurance coverage, and fuel expenses that fluctuate with market conditions. The stop-and-go nature of residential deliveries increases fuel consumption and vehicle wear, leading to higher operational costs per package delivered. Failed delivery attempts multiply these expenses as drivers must return to the same locations multiple times.

Route optimization becomes increasingly complex as delivery density decreases and customer expectations for specific delivery windows increase. Urban congestion and parking challenges further extend delivery times and increase fuel consumption. These factors combine to create a cost structure where traditional delivery methods become less economical as package volumes grow and customer demands evolve.

The Economic Impact of Failed Delivery Attempts

Quantifying Redelivery Costs

Failed delivery attempts represent one of the most significant hidden costs in traditional courier operations. Industry studies indicate that unsuccessful delivery attempts occur in approximately 15-20% of residential deliveries, forcing companies to invest additional resources in subsequent delivery efforts. Each failed attempt requires the same vehicle resources, driver time, and fuel consumption as successful deliveries, effectively doubling or tripling the cost of affected packages. These redelivery expenses accumulate rapidly across large delivery networks, representing millions of dollars in unnecessary operational costs.

The ripple effects of failed deliveries extend beyond immediate redelivery costs to include customer service expenses, package storage fees, and potential customer churn. Customer service representatives must handle inquiries about missed deliveries, reschedule delivery attempts, and manage customer frustration. Packages requiring multiple delivery attempts consume warehouse space and handling resources while generating no additional revenue. This operational inefficiency creates a compounding cost structure that smart parcel lockers can effectively address.

Storage and Handling Overhead

Packages awaiting redelivery create additional storage and handling requirements within courier company facilities. These items occupy valuable warehouse space, require additional sorting and tracking processes, and increase the complexity of inventory management systems. The cost of temporary storage extends beyond physical space to include labor for package handling, security measures, and administrative processes for tracking delayed deliveries. This overhead grows proportionally with the number of failed delivery attempts across the network.

Temperature-sensitive or valuable packages requiring special storage conditions add another layer of complexity and cost to the redelivery process. These items may require climate-controlled environments or enhanced security measures, increasing the per-package cost of storage. The longer packages remain in the delivery system due to failed attempts, the higher these ancillary costs become, creating a compelling economic argument for delivery solutions that reduce redelivery rates.

How Smart Parcel Lockers Transform Delivery Economics

Eliminating Multiple Delivery Attempts

The implementation of smart parcel lockers fundamentally changes the delivery equation by providing a secure, accessible location for package drop-off regardless of recipient availability. This automated system eliminates the primary cause of failed delivery attempts by creating a 24/7 accessible pickup point that accommodates varying customer schedules. Courier companies can complete deliveries on the first attempt, dramatically reducing the labor and fuel costs associated with multiple delivery efforts.

The consolidation of multiple deliveries to a single locker location creates additional efficiency gains through route optimization. Drivers can deliver numerous packages to one secure location rather than visiting individual addresses, reducing travel time, fuel consumption, and vehicle wear. This batch delivery approach maximizes the utilization of delivery resources while minimizing the time and cost per package delivered. The result is a more predictable and efficient delivery model that scales effectively with increasing package volumes.

Optimized Route Planning and Density

Smart parcel lockers enable courier companies to implement more efficient route planning strategies by creating high-density delivery points within residential and commercial areas. Instead of dispersing delivery attempts across numerous individual addresses, drivers can focus on servicing locker locations that aggregate multiple packages for entire neighborhoods or building complexes. This concentration effect reduces the total distance traveled per package delivered and increases the number of successful deliveries per route.

The predictable nature of locker locations allows for more sophisticated route optimization algorithms that can minimize travel time and fuel consumption across entire delivery networks. Courier companies can leverage data analytics to determine optimal locker placement, predict package volumes, and schedule deliveries during off-peak traffic periods. This strategic approach to route planning translates directly into reduced operational costs and improved delivery efficiency metrics that benefit both the company and its customers.

Operational Efficiency Gains Through Automation

Reduced Labor Requirements

The automated nature of smart parcel lockers significantly reduces the labor intensity of package delivery operations. Drivers can complete deliveries without waiting for recipients, eliminating time spent attempting to locate customers or leaving delivery notices. This efficiency improvement allows courier companies to serve more customers with existing staff levels or reduce labor costs while maintaining service coverage. The time savings compound across entire delivery routes, enabling drivers to complete more deliveries per shift and improving overall productivity metrics.

Customer service requirements also decrease with smart parcel lockers implementation, as automated notifications and self-service pickup reduce the need for customer inquiries about delivery status. The system handles package tracking, pickup notifications, and basic customer interactions automatically, freeing customer service representatives to focus on more complex issues. This reduction in customer service volume translates directly into labor cost savings and improved customer satisfaction through faster issue resolution.

Streamlined Package Handling Processes

Smart parcel lockers integrate seamlessly with existing courier company logistics systems, automating many of the manual processes associated with traditional delivery methods. Package sorting, tracking updates, and delivery confirmation occur automatically through integrated software systems, reducing the potential for human error and eliminating manual data entry requirements. This automation extends throughout the delivery chain, from initial package receipt to final customer pickup confirmation.

The standardized nature of locker deliveries simplifies training requirements for delivery personnel and reduces the complexity of package handling procedures. Drivers follow consistent protocols for locker deliveries regardless of location, creating operational efficiencies that scale across entire delivery networks. This standardization also facilitates quality control measures and performance monitoring, enabling courier companies to maintain consistent service levels while reducing operational overhead.

Technology Integration and Scalability Benefits

Real-Time Tracking and Analytics

Modern smart parcel lockers incorporate advanced tracking and analytics capabilities that provide courier companies with unprecedented visibility into delivery operations. Real-time data on package volumes, pickup rates, and locker utilization enable companies to make informed decisions about resource allocation and network optimization. This data-driven approach to operations management helps identify cost-saving opportunities and improve overall system efficiency through evidence-based decision making.

The integration of locker systems with courier company databases creates seamless information flow that reduces administrative overhead and improves customer communication. Automated status updates, pickup notifications, and exception handling reduce the need for manual intervention while providing customers with timely information about their packages. This technological integration creates operational efficiencies that translate directly into cost reductions and improved customer satisfaction metrics.

Scalable Infrastructure Investment

Smart parcel lockers represent a scalable infrastructure investment that can grow with increasing package volumes without proportional increases in operational costs. Unlike traditional delivery methods that require additional vehicles, drivers, and fuel for expansion, locker networks can accommodate volume growth through efficient utilization of existing infrastructure. This scalability advantage becomes increasingly valuable as e-commerce growth drives higher package delivery demands across urban and suburban markets.

The modular nature of locker systems allows courier companies to expand coverage areas strategically based on demand patterns and cost-benefit analysis. New locations can be added incrementally to serve growing customer bases without major infrastructure investments or operational disruptions. This flexibility enables companies to respond quickly to market opportunities while maintaining cost-effective operations that support long-term profitability goals.

Customer Satisfaction and Retention Benefits

Enhanced Delivery Convenience

Smart parcel lockers significantly improve customer satisfaction by providing convenient, secure package pickup options that accommodate diverse schedules and preferences. Customers can retrieve packages at their convenience without waiting for delivery attempts or rescheduling delivery windows. This flexibility reduces customer frustration and complaints, leading to improved customer retention rates and reduced customer service costs for courier companies.

The security features of smart parcel lockers address customer concerns about package theft and weather damage, providing peace of mind that traditional doorstep deliveries cannot match. Climate-controlled environments and secure access systems protect packages from environmental damage and unauthorized access, reducing insurance claims and replacement costs for courier companies. These security benefits create additional value propositions that justify premium pricing for delivery services.

Reduced Customer Service Demands

The self-service nature of smart parcel lockers significantly reduces customer service inquiries related to delivery issues, package location, and delivery scheduling. Automated notifications and clear pickup instructions minimize confusion and reduce the need for customer support intervention. This reduction in customer service volume translates directly into cost savings through reduced staffing requirements and improved service quality for remaining customer interactions.

Customer empowerment through self-service options creates positive experiences that enhance brand perception and customer loyalty. The ability to track packages in real-time and receive immediate pickup notifications gives customers greater control over their delivery experience. This improved customer satisfaction leads to higher retention rates, positive word-of-mouth marketing, and reduced customer acquisition costs that benefit long-term business profitability.

FAQ

What are the primary cost savings courier companies achieve with smart parcel lockers?

Courier companies typically achieve cost savings of 20-30% per package delivered through smart parcel lockers by eliminating redelivery attempts, reducing labor costs, optimizing delivery routes, and decreasing customer service requirements. The automated nature of locker systems also reduces operational overhead while improving delivery success rates and customer satisfaction.

How do smart parcel lockers improve delivery efficiency compared to traditional methods?

Smart parcel lockers improve delivery efficiency by enabling first-attempt success rates of over 95%, allowing drivers to complete multiple deliveries at single locations, and reducing time spent per delivery through automated processes. This efficiency improvement translates to more packages delivered per route and reduced operational costs per package.

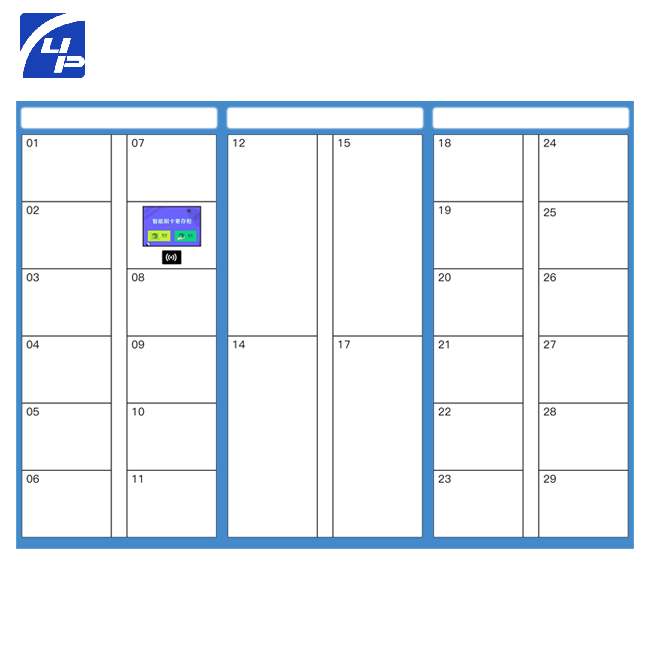

Can smart parcel lockers accommodate different package sizes and special requirements?

Modern smart parcel lockers feature multiple compartment sizes and can accommodate packages up to specific weight and dimension limits. Many systems also include temperature-controlled compartments for sensitive items and enhanced security features for valuable packages, providing flexible solutions for diverse delivery requirements while maintaining cost-effective operations.

How do smart parcel lockers integrate with existing courier company systems?

Smart parcel lockers integrate seamlessly with existing courier management systems through API connections and standardized data formats. This integration enables real-time tracking updates, automated customer notifications, and streamlined operational processes that work with current logistics software and procedures without requiring major system overhauls.

Table of Contents

- Understanding the Cost Structure of Traditional Parcel Delivery

- The Economic Impact of Failed Delivery Attempts

- How Smart Parcel Lockers Transform Delivery Economics

- Operational Efficiency Gains Through Automation

- Technology Integration and Scalability Benefits

- Customer Satisfaction and Retention Benefits

-

FAQ

- What are the primary cost savings courier companies achieve with smart parcel lockers?

- How do smart parcel lockers improve delivery efficiency compared to traditional methods?

- Can smart parcel lockers accommodate different package sizes and special requirements?

- How do smart parcel lockers integrate with existing courier company systems?